Nemix Alloys line of copper strips also includes strips that have smooth and polished surfaces with deburred edges for transformer windings. The precision deburring is done on ahighly sophisticated line which makes these strips ideal for electric windings in large transformers. The transformer strips are made of ETP copper with tolerances within the limits imposed by the EN 1652 standard

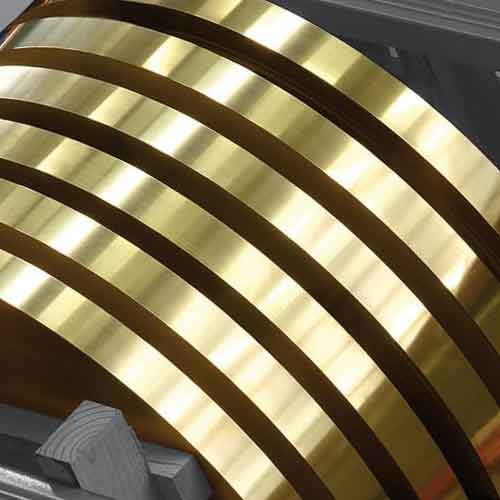

Nexim Alloys manufactures Brass Strips and Foils in the thickness range of 2.5mm to 0.05mm and width range of 20mm to 400mm with maximum coil weight of 8 Kgs per mm width.

The transformer strips are made of ETP copper with tolerances within the limits imposed by the EN 1652 standard.

Nexim Alloys also produces special copper and copper-alloy strips used for the production of precision cables for telecommunications: coaxial cables, HF for high frequency data transmission and submarine communication cables.

For specific welding requirements, Nexim Alloys can supply cable strips with the following features:

In addition, Nexim Alloys supplies special strips such as perforated strips which are used in radiating cables.

For more information on the production and size range visit the specific sections of this site regarding

Nexim Alloys cast Brass Alloys on Technica Guss (Germany) - Comptucast Horizontal Continuous Casting line (HCC Line) with channel type Melting/Holding Furnace by casting Strips upto 450 mm width in thickness of 14 mm thickness with In-Line Milling Machine to remove all the Oxides from both the surfaces.

Nexim Alloys manufactures Brass Strips and Foils in the thickness range of 2.5mm to 0.05mm and width range of 20mm to 400mm with maximum coil weight of 8 Kgs per mm width.

Tin Bearing Copper has a distinguished quality of being resistant to annealing therefore is very suitable for Automotive and Refrigeration Radiator Fins applications.

Nexim Alloys manufactures Brass Strips and Foils in the thickness range of 2.5mm to 0.05mm and width range of 20mm to 350mm with maximum coil weight of 8 Kgs per mm width.